Plywood Weight, OSB Weight & More • Calculator & Charts

Including Weights for MDF, MDO, and Particle Board

By Jack Gray, Roof Online Editor • Last updated November 24, 2023

Table of Contents

Plywood Weight Calculator

Plywood weight calculator notes:

- CDX plywood is a grade of softwood plywood.

- When entering a plywood thickness greater than 1 that contains a fraction, such as 1 1/8, make sure to include a space between the whole number and the fraction. Type in “1 1/8”, not “11/8”.

- The weight values produced by this calculator are based on the values in the charts below, but may vary slightly due to rounding.

- This calculator is intended to give you an idea of what plywood weighs, but even the same type of plywood panel with the same dimensions can vary in weight from product to product. Always check with the manufacturer for the weights of specific products.

Plywood Weight Calculator

What is Plywood Made of?

Plywood is composed of approximately 90% – 97% wood, with the remainder made up by primers, sealants, and adhesives such as phenol formaldehyde resin.

Other engineered wood panel types, such as particle board or OSB, contain a much higher percentage of adhesive resin, and since these resins are heavier than wood, these panels tend to be significantly heavier than plywood.

Plywood Weight Factors

Plywood weight is determined by the length, width, and thickness of the panel, as well as the wood species and the types and amounts of adhesives, primers, and sealants used to make the plywood. This goes for all other types of engineered wood panels as well.

Plywood, OSB, particle board, etc. are manufactured using adhesives, primers, and sealants. Some of these panel types require quite a bit more of these materials than other types. For instance, while plywood is typically 90% to 97% wood, OSB might only contain 80% wood.

Since adhesive resins and sealants are much heavier than wood, this means that wood products that use a lot of them will be heavier than wood products that use less of them. For instance, OSB tends to be around 20% to 25% heavier than softwood plywood, OSB’s main competitor in the construction industry.

Another factor in plywood weight is the wood species used to make the panel. Different wood species have naturally different densities, and this can make a big difference in the weight of the finished product.

The use of different wood species and different proportions of adhesive by different manufacturers can result in weight differences of up to 20% for plywood or OSB panels with the exact same dimensions and product description from one manufacturer to the next, or even for different batches of the same product from the same manufacturer.

About Our Plywood Weight & Thickness Charts

The following tables provide typical weights (dead load, self-weight) for plywood, OSB, and other engineered wood panels according to thickness and panel type.

The plywood thicknesses we include cover most of the standard panel thicknessess available from engineered wood panel manufacturers today.

We provide metric and US standard plywood weights for whole standard sheets of various common thicknesses, as well as plywood weights per square foot, and plywood weights per square meter.

The plywood weights we give were calculated using the product data sheets or manufacturer specifications of actual, specific wood panel products, and in most cases our plywood weights are the average of product weights from more than one manufacturer.

Table 1: Plywood Weights in Pounds per Square Foot

| Weight of Plywood, OSB, and Other Engineered Wood Panels in Pounds per Square Foot (lb/ft²) by Panel Thickness |

||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Panel Type | Panel Thickness in Inches | |||||||||||

| ↓ | 1/4″ | 11/32″ | 3/8″ | 15/32″ | 1/2″ | 19/32″ | 5/8″ | 23/32″ | 3/4″ | 7/8″ | 1″ | 1⅛” |

| APA Plywood Standard |

0.80 lb/ft² |

1.00 lb/ft² |

1.10 lb/ft² |

1.40 lb/ft² |

1.50 lb/ft² |

1.70 lb/ft² |

1.80 lb/ft² |

2.10 lb/ft² |

2.20 lb/ft² |

2.60 lb/ft² |

3.00 lb/ft² |

3.30 lb/ft² |

| Baltic Birch Plywood |

0.92 lb/ft² |

1.15 lb/ft² |

1.26 lb/ft² |

1.61 lb/ft² |

1.72 lb/ft² |

1.95 lb/ft² |

2.06 lb/ft² |

2.41 lb/ft² |

2.54 lb/ft² |

2.98 lb/ft² |

3.44 lb/ft² |

3.78 lb/ft² |

| Hardwood Plywood |

0.80 lb/ft² |

1.00 lb/ft² |

1.10 lb/ft² |

1.40 lb/ft² |

1.50 lb/ft² |

1.70 lb/ft² |

1.80 lb/ft² |

2.10 lb/ft² |

2.20 lb/ft² |

2.60 lb/ft² |

3.00 lb/ft² |

3.30 lb/ft² |

| Marine Plywood |

0.85 lb/ft² |

1.06 lb/ft² |

1.17 lb/ft² |

1.49 lb/ft² |

1.60 lb/ft² |

1.81 lb/ft² |

1.92 lb/ft² |

2.23 lb/ft² |

2.34 lb/ft² |

2.77 lb/ft² |

3.19 lb/ft² |

3.51 lb/ft² |

| Pressure-Treated Plywood |

1.00 lb/ft² |

1.25 lb/ft² |

1.37 lb/ft² |

1.75 lb/ft² |

1.87 lb/ft² |

2.12 lb/ft² |

2.24 lb/ft² |

2.62 lb/ft² |

2.74 lb/ft² |

3.24 lb/ft² |

3.74 lb/ft² |

4.11 lb/ft² |

| Softwood Plywood |

0.72 lb/ft² |

0.90 lb/ft² |

0.99 lb/ft² |

1.26 lb/ft² |

1.35 lb/ft² |

1.53 lb/ft² |

1.62 lb/ft² |

1.89 lb/ft² |

1.98 lb/ft² |

2.34 lb/ft² |

2.70 lb/ft² |

2.97 lb/ft² |

| MDF | 1.15 lb/ft² |

1.44 lb/ft² |

1.58 lb/ft² |

2.01 lb/ft² |

2.16 lb/ft² |

2.44 lb/ft² |

2.59 lb/ft² |

3.02 lb/ft² |

3.16 lb/ft² |

3.74 lb/ft² |

4.31 lb/ft² |

4.74 lb/ft² |

| MDO | 0.80 lb/ft² |

1.00 lb/ft² |

1.10 lb/ft² |

1.40 lb/ft² |

1.50 lb/ft² |

1.70 lb/ft² |

1.80 lb/ft² |

2.10 lb/ft² |

2.20 lb/ft² |

2.60 lb/ft² |

3.00 lb/ft² |

3.30 lb/ft² |

| Particle Board | 1.08 lb/ft² |

1.35 lb/ft² |

1.49 lb/ft² |

1.90 lb/ft² |

2.03 lb/ft² |

2.30 lb/ft² |

2.44 lb/ft² |

2.84 lb/ft² |

2.98 lb/ft² |

3.52 lb/ft² |

4.06 lb/ft² |

4.47 lb/ft² |

| Panel Type | Panel Thickness in Inches | |||||||||||

| ↓ | 1/4″ | 5/16″ | 3/8″ | 7/16″ | 15/32″ | 1/2″ | 19/32″ | 5/8″ | 23/32″ | 3/4″ | 7/8″ | 1″ |

| OSB | 0.90 lb/ft² |

1.10 lb/ft² |

1.20 lb/ft² |

1.40 lb/ft² |

1.50 lb/ft² |

1.70 lb/ft² |

2.00 lb/ft² |

2.10 lb/ft² |

2.40 lb/ft² |

2.50 lb/ft² |

2.90 lb/ft² |

3.30 lb/ft² |

Table 2: Plywood Weights in Pounds per Standard Sheet

| Weight of Plywood, OSB, and Other Engineered Wood Panels In Pounds per Standard Sheet (4 feet x 8 feet) by Panel Thickness |

||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Panel Type | Panel Thickness in Inches | |||||||||||

| ↓ | 1/4″ | 11/32″ | 3/8″ | 15/32″ | 1/2″ | 19/32″ | 5/8″ | 23/32″ | 3/4″ | 7/8″ | 1″ | 1⅛” |

| APA Plywood Standard |

26 lb | 32 lb | 35 lb | 45 lb | 48 lb | 54 lb | 58 lb | 67 lb | 70 lb | 83 lb | 96 lb | 106 lb |

| Baltic Birch Plywood |

29 lb | 37 lb | 40 lb | 52 lb | 55 lb | 62 lb | 66 lb | 77 lb | 81 lb | 95 lb | 110 lb | 121 lb |

| Hardwood Plywood |

26 lb | 32 lb | 35 lb | 45 lb | 48 lb | 54 lb | 58 lb | 67 lb | 70 lb | 83 lb | 96 lb | 106 lb |

| Marine Plywood |

27 lb | 34 lb | 37 lb | 48 lb | 51 lb | 58 lb | 61 lb | 71 lb | 75 lb | 89 lb | 102 lb | 112 lb |

| Pressure-Treated Plywood |

32 lb | 40 lb | 44 lb | 56 lb | 60 lb | 68 lb | 72 lb | 84 lb | 88 lb | 104 lb | 120 lb | 132 lb |

| Softwood Plywood |

23 lb | 29 lb | 32 lb | 40 lb | 43 lb | 49 lb | 52 lb | 60 lb | 63 lb | 75 lb | 86 lb | 95 lb |

| MDF | 37 lb | 46lb | 51 lb | 64 lb | 69 lb | 78 lb | 83 lb | 97 lb | 101 lb | 120 lb | 138 lb | 152 lb |

| MDO | 26 lb | 32 lb | 35 lb | 45 lb | 48 lb | 54 lb | 58 lb | 67 lb | 70 lb | 83 lb | 96 lb | 106 lb |

| Particle Board | 35 lb | 43 lb | 48 lb | 61 lb | 65 lb | 74 lb | 78 lb | 91 lb | 95 lb | 113 lb | 130 lb | 143 lb |

| Panel Type | Panel Thickness in Inches | |||||||||||

| ↓ | 1/4″ | 5/16″ | 3/8″ | 7/16″ | 15/32″ | 1/2″ | 19/32″ | 5/8″ | 23/32″ | 3/4″ | 7/8″ | 1″ |

| OSB | 29 lb | 35 lb | 38 lb | 45 lb | 48 lb | 54 lb | 64 lb | 67 lb | 77 lb | 80 lb | 93 lb | 106 lb |

Table 3: Plywood Weights in Kilograms per Square Meter

| Weight of Plywood, OSB, and Other Engineered Wood Panels In Kilograms per Square Meter (kg/m²) by Panel Thickness |

||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Panel Type | Panel Thickness in Millimeters | |||||||||

| ↓ | 6 mm | 9 mm | 12 mm | 15 mm | 18 mm | 21 mm | 24 mm | 25 mm | 28 mm | 30 mm |

| Baltic Birch Plywood |

4.20 kg/m² |

5.85 kg/m² |

7.80 kg/m² |

9.75 kg/m² |

11.67 kg/m² |

13.65 kg/m² |

15.61 kg/m² |

16.25 kg/m² |

18.20 kg/m² |

19.50 kg/m² |

| Hardwood Plywood |

3.65 kg/m² |

5.09 kg/m² |

6.78 kg/m² |

8.48 kg/m² |

10.15 kg/m² |

11.87 kg/m² |

13.57 kg/m² |

14.13 kg/m² |

15.83 kg/m² |

16.96 kg/m² |

| Marine Plywood |

3.87 kg/m² |

5.40 kg/m² |

7.19 kg/m² |

8.99 kg/m² |

10.76 kg/m² |

12.58 kg/m² |

14.38 kg/m² |

14.98 kg/m² |

16.78 kg/m² |

17.98 kg/m² |

| Pressure-Treated Plywood |

4.56 kg/m² |

6.36 kg/m² |

8.48 kg/m² |

10.60 kg/m² |

12.69 kg/m² |

14.84 kg/m² |

16.96 kg/m² |

17.66 kg/m² |

19.79 kg/m² |

21.20 kg/m² |

| Softwood Plywood |

3.29 kg/m² |

4.58 kg/m² |

6.10 kg/m² |

7.63 kg/m² |

9.14 kg/m² |

10.68 kg/m² |

12.21 kg/m² |

12.72 kg/m² |

14.25 kg/m² |

15.26 kg/m² |

| MDF | 5.26 kg/m² |

7.33 kg/m² |

9.76 kg/m² |

12.21 kg/m² |

14.62 kg/m² |

17.09 kg/m² |

19.54 kg/m² |

20.35 kg/m² |

22.80 kg/m² |

24.42 kg/m² |

| MDO | 3.65 kg/m² |

5.09 kg/m² |

6.78 kg/m² |

8.48 kg/m² |

10.15 kg/m² |

11.87 kg/m² |

13.57 kg/m² |

14.13 kg/m² |

15.83 kg/m² |

16.96 kg/m² |

| OSB | 4.15 kg/m² |

5.75 kg/m² |

7.66 kg/m² |

9.58 kg/m² |

11.47 kg/m² |

13.41 kg/m² |

15.33 kg/m² |

15.97 kg/m² |

17.89 kg/m² |

19.16 kg/m² |

| Particle Board | 4.93 kg/m² |

6.87 kg/m² |

9.15 kg/m² |

11.45 kg/m² |

13.70 kg/m² |

16.02 kg/m² |

18.32 kg/m² |

19.08 kg/m² |

21.37 kg/m² |

22.90 kg/m² |

Table 4: Plywood Weights in Kilograms per Standard Sheet

| Weight of Plywood, OSB, and Other Engineered Wood Panels In Kilograms per Standard Sheet (1220 mm x 2440 mm) by Panel Thickness |

||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Panel Type | Panel Thickness in Millimeters | |||||||||

| ↓ | 6 mm | 9 mm | 12 mm | 15 mm | 18 mm | 21 mm | 24 mm | 25 mm | 28 mm | 30 mm |

| Baltic Birch Plywood |

12.50 kg | 17.41 kg | 23.22 kg | 29.02 kg | 34.74 kg | 40.63 kg | 46.47 kg | 48.37 kg | 54.18 kg | 58.05 kg |

| Hardwood Plywood |

10.87 kg | 15.15 kg | 20.18 kg | 25.24 kg | 30.21 kg | 35.33 kg | 40.40 kg | 42.06 kg | 47.12 kg | 50.49 kg |

| Marine Plywood |

11.52 kg | 16.07 kg | 21.40 kg | 26.76 kg | 32.03 kg | 37.45 kg | 42.81 kg | 44.59 kg | 49.95 kg | 53.52 kg |

| Pressure-Treated Plywood |

13.57 kg | 18.93 kg | 25.24 kg | 31.55 kg | 37.78 kg | 44.18 kg | 50.49 kg | 52.57 kg | 58.91 kg | 63.11 kg |

| Softwood Plywood |

9.79 kg | 13.63 kg | 18.16 kg | 22.71 kg | 27.21 kg | 31.79 kg | 36.35 kg | 37.86 kg | 42.42 kg | 45.43 kg |

| MDF | 15.66 kg | 21.82 kg | 29.05 kg | 36.35 kg | 43.52 kg | 50.87 kg | 58.17 kg | 60.58 kg | 67.87 kg | 72.69 kg |

| MDO | 10.87 kg | 15.15 kg | 20.18 kg | 25.24 kg | 30.21 kg | 35.33 kg | 40.40 kg | 42.06 kg | 47.12 kg | 50.49 kg |

| OSB | 12.35 kg | 17.12 kg | 22.80 kg | 28.52 kg | 34.14 kg | 39.92 kg | 45.63 kg | 47.54 kg | 53.25 kg | 57.04 kg |

| Particle Board | 14.68 kg | 20.45 kg | 27.24 kg | 34.08 kg | 40.78 kg | 47.69 kg | 54.53 kg | 56.80 kg | 63.61 kg | 68.17 kg |

Types of Plywood and Other Engineered Wood Panels

APA Standard Plywood Weight

APA Plywood Standard: The Engineered Wood Association (formerly the American Plywood Association) provides standard notional plywood weights for use in determining expected dead loads when performing structural engineering calculations.

Softwood plywood is typically used as structural plywood (roof decking, sheathing, flooring).

The APA Standard plywood weights are not weights for actual products and tend to be somewhat heavier than the weights of any real softwood plywood you will find.

A 4’ x 8’ sheet of 1/2-inch APA Standard Plywood would weigh 48 lbs.

Baltic Birch Plywood Weight

Baltic Birch Plywood: This is a high-quality plywood traditionally produced in Russia and other areas around the Baltic Sea. (Forests around the Baltic Sea can be up to 28% birch trees.)

This type of plywood is made up entirely of birch wood, so unlike some other hardwood plywood, it does not use softwood for the inner plies, and the inner plies are void-free, increasing its stability. Baltic birch plywood is used mostly for furniture-making and cabinetry.

A 4’ x 8’ sheet of 1/2-inch Baltic Birch Plywood weighs around 55 lbs.

See Baltic Birch Plywood on Amazon

Hardwood Plywood Weight

Hardwood Plywood: At least the front and back veneers (outer plies) of hardwood plywood will be made of a hardwood species such as maple or oak.

Although the inner plies may also be hardwood, more often they will be made of a cheaper softwood species. The hardwood veneers improve strength, stability, and impact-resistance.

Hardwood plywood is commonly used in applications where these qualities are desired, like flooring, cabinets, or wall paneling.

A typical 4’ x 8’ sheet of 1/2-inch Hardwood Plywood weighs around 48 lbs.

See Hardwood Plywood at the Home Depot

Marine Plywood Weight

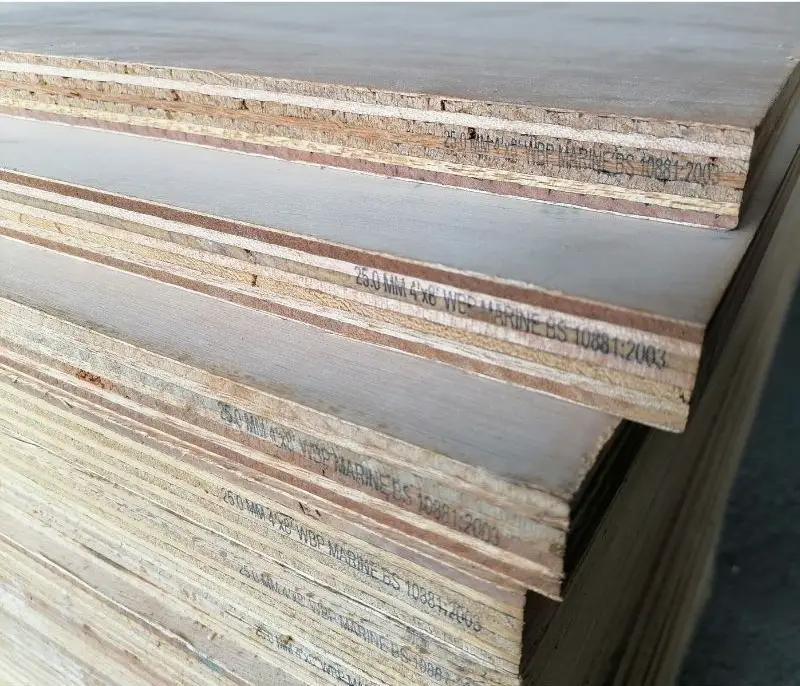

Marine Plywood: Despite its name, this is not a waterproof plywood. Marine plywood is manufactured using specially formulated water-resistant adhesive and very dense, high-quality outer plies. These high-quality outer veneers serve to help prevent moisture from penetrating the panel.

Marine plywood is designed to be used where the material will be subjected to higher-than-normal amounts of moisture, such as marinas and other coastal environments.

A typical 4’ x 8’ sheet of 1/2-inch Marine Plywood weighs around 51 lbs.

Pressure-Treated Plywood Weight

Pressure-Treated Plywood: This is usually a softwood plywood that has been pressure-treated to help it resist decay caused by fungus, insects, and other organisms.

Southern yellow pine is particularly well-suited for pressure treating, and most pressure-treated plywood is made from southern yellow pine. Special waterproof adhesives are used when this plywood is manufactured so it can withstand the pressure-treating process without falling apart.

Pressure-treated plywood uses relatively more adhesive than other plywoods. Because of this and the fact that the southern yellow pine used is much heavier than other wood species used in construction, pressure-treated plywood tends to be a heavy plywood.

Pressure-treated plywood is heavier than other plywoods even after drying out from the pressure-treating process. Before drying out, of course, it can be much, much heavier.

A typical 4’ x 8’ sheet of 1/2-inch Pressure-Treated Plywood weighs around 60 lbs.

See Pressure-Treated Plywood at the Home Depot

Softwood Plywood Weight

Softwood Plywood: This is the type of plywood most commonly used in construction.

When people talk about structural plywood, it’s almost always softwood plywood that they’re talking about. Softwood plywood is used for roof sheathing, wall sheathing, subfloors, and more.

Softwood plywood comes from coniferous trees, primarily fir, pine, or spruce. It is generally the lightest type of engineered wood panel, due to the light weight of the wood species used and the (relatively) low amount of adhesive used in the manufacturing process. Softwood plywood weight is further reduced by the presence of unfilled voids within the inner plies.

Softwood plywood is normally the cheapest plywood. CDX plywood, the most common plywood used for roof sheathing, is a grade of softwood plywood.

A typical 4’ x 8’ sheet of 1/2-inch Softwood Plywood weighs around 43 lbs.

See Softwood Plywood at the Home Depot

MDF Panel Weight

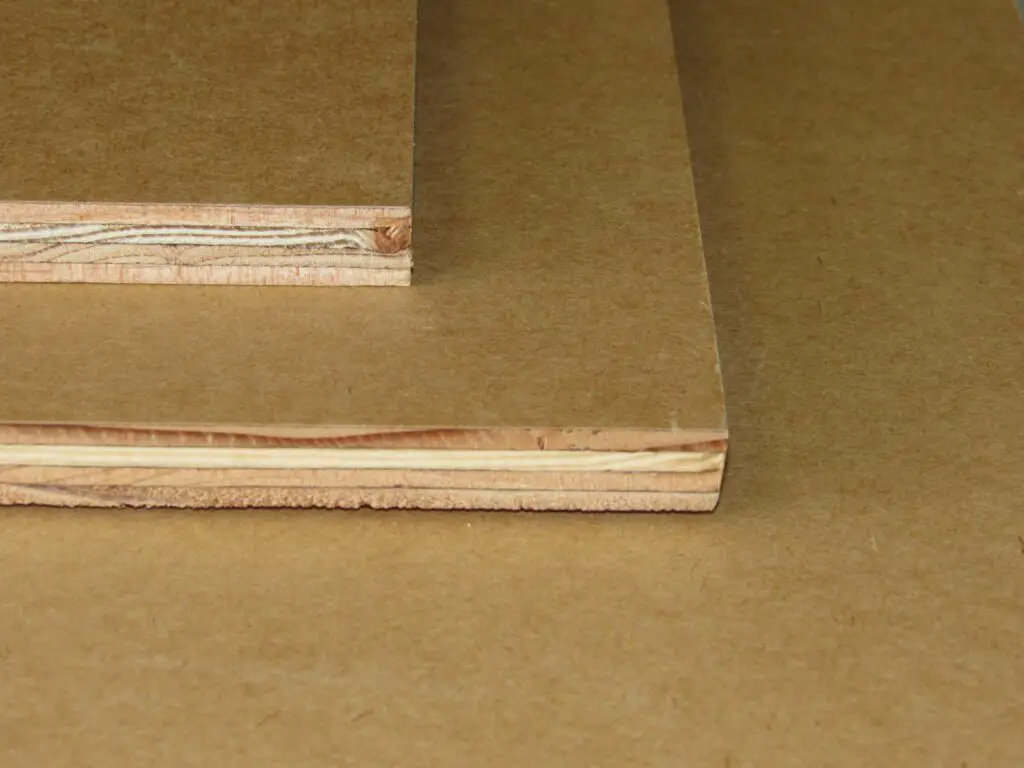

MDF: Medium Density Fiberboard is produced from wood scraps left over from other wood product manufacturing activities.

This waste wood can be either hardwood or softwood. The scraps are broken down into very small wood fibers, which are combined with wax and adhesive resin to form the MDF panels.

MDF does not handle moisture well, and is normally only used for interior applications, such as flooring or furniture.

Because of the extremely high resin content, MDF tends to be one of the heaviest types of engineered wood panels.

A typical 4’ x 8’ sheet of 1/2-inch MDF weighs around 69 lbs.

MDO Panel Weight

MDO: Medium Density Overlay is a type of exterior plywood specifically designed to be painted easily. The use of MDO for sign boards is very common. Due to its extremely smooth surface, it holds paint better, and looks better after being painted, than other types of engineered wood panels.

The wood plies in MDO panels are typically softwood, and a thick, smooth layer (the overlay) of a highly water-resistant resin is applied to either one or both sides of the panel.

A typical 4’ x 8’ sheet of 1/2-inch MDO weighs around 48 lbs.

Particle Board Weight

Particle Board: The product generally known as “particle board” is similar to MDF.

It is made with similar manufacturing techniques, but the end product is cheaper, weaker, and of lower density. It is also called LDF (low density fiberboard).

A typical 4’ x 8’ sheet of 1/2-inch Particle Board weighs around 66 lbs.

OSB Weight

OSB: Oriented Strand Board is plywood’s biggest competitor as a structural wood panel in North America.

In large-scale commercial construction, OSB has largely replaced softwood plywood in wall sheathing, roof sheathing, and subflooring applications. This, of course, is due to the fact that a sheet of OSB costs about 20% less than the equivalent sheet of plywood.

OSB is made by breaking down wood into small strips, or “strands”, up to 6 inches long, combining these strands with wax and adhesive resin under pressure and heat to form layers.

The strands in each layer are all generally “oriented” in the same direction. These layers are combined to form OSB panels of the desired panel thickness.

The wood strands in the outer layers are oriented one way, and the strands in the interior layers are oriented the other way, which increases panel strength.

OSB is manufactured in a slightly different range of thicknesses than plywood.

A typical 4′ x 8′ sheet of 1/2-inch OSB weighs around 54 lbs.

Ask the Lumber Company!

Remember, the values for plywood weight, OSB weight, etc. given in our weight tables are meant to provide a general idea of typical engineered wood panel weights, and should not be used if precise values are needed for critical engineering calculations.

When precision is necessary, always refer to the specification sheet for the actual, specific product you intend to use, or contact the technical department of the panel manufacturer.

Most lumber yards or plywood manufacturers will list a phone number for their technical department on the contact page on their website. Go ahead and call it if you have any questions!

About the Author

Jack Gray is a principal roof consultant and vice president at the Moriarty Corporation, an award-winning building enclosure consultant firm founded in 1967. He is also the editor of the Roof Online website.

Mr. Gray has worked in the roofing industry for over 25 years, with training and practical experience in roof installation, roof inspection, roof safety, roof condition assessment, construction estimating, roof design & specification, quality assurance, roof maintenance & repair, and roof asset management.

He was awarded the Registered Roof Observer (RRO) professional credential in 2009.

He also served as an infantry paratrooper in the 82nd Airborne Division and attended Cornell University. Read full bio.