Tensile Fabric Roofing Manufacturers List & Website Directory

By Jack Gray, Roof Online Editor • Last updated August 6, 2024

To learn more about fabric roofing, see our Fabric Roofing page.

Return to the Roofing Manufacturer Directory Index

What is Tensile Fabric?

Tensile fabric should be familiar to anyone who flies a lot and passes through major airports. It’s a popular material used to protect open areas like walkways, pick-up and drop-off locations, and long-term parking lots. Tensile fabric is an engineered material used to cover outdoor spaces without the need for a normal supporting structure (like a building!).

These fabrics are extremely lightweight and are created using woven fabric base layers, often made from polyester or fiberglass, which are coated with protective layers of PVC, PTFE (Teflon), or silicone. These compositions and formulations guarantee the strength, flexibility, and resistance to UV rays, moisture, and hail necessary for a successful roofing material.

Use as Roofing

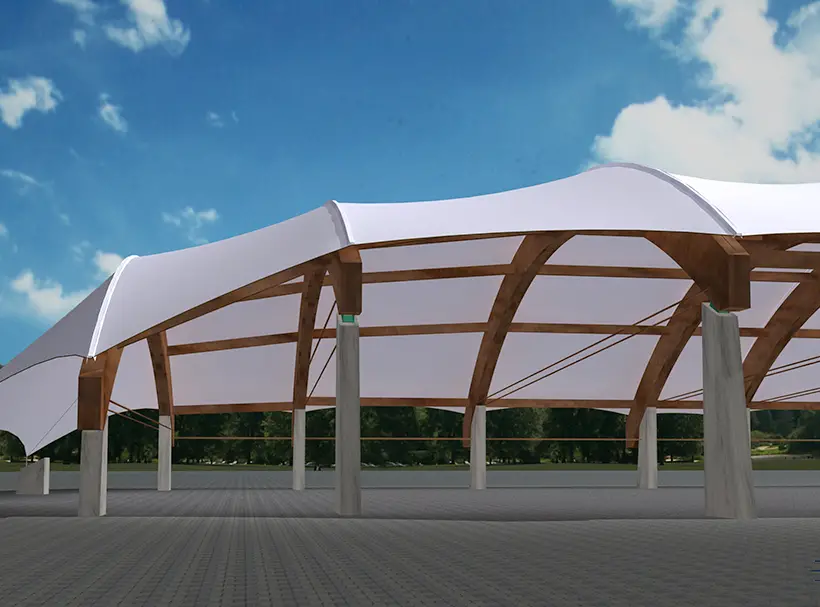

Tensile fabric is typically used to provide the benefits of a roof where an actual building is not needed or wanted. It can be used to create interesting, neat-looking structures that are also functional. It is used to design and construct roofs that span large areas without the need for internal supports, allowing for extensive unobstructed spaces below. Places you might find tensile fabric roofs include sports stadiums, outdoor music venues, airport terminals, and exhibition centers. The versatility of tensile fabric allows architects to experiment with complex, unique roof shapes that would be difficult or impossible to achieve with standard materials.

Protective Layers on Tensile Fabric

A high-quality formulation and application of the surface layer is generally the key to the performance and service life of tensile fabrics. PVC is popular for its lower price and has a service life of around 15 to 20 years. PTFE, or Teflon, is used for higher-end applications; it’s capable of withstanding extreme weather conditions, is chemically inert, and can last for more than 30 years. Silicone coatings are less expensive than PTFE but more UV resistant, translucent, and longer-lasting than PVC.

These surface layers/coatings protect the fabric from weathering, dirt, and UV damage, and extend the lifespan of the fabric.

Types of Tensile Fabric and Their Uses

- Polyester Fabric Coated with PVC: This is the most commonly seen type of tensile fabric roofing, typically used for applications where a long service life is not a primary concern, such as large tents and other temporary structures.

- Glass Fiber Fabric Coated with PTFE or Silicone: Fiberglass fabric is known for its strength and resistance to extreme temperatures and discoloration; this type of tensile fabric is normally used for permanent structures that require a longer lifespan, such as stadium roofs or large pavilions.

- ETFE (Ethylene Tetrafluoroethylene): Not a typical fabric but a type of soft fluoropolymer film used similarly to tensile fabrics. It’s very lightweight, long-lasting, and can be highly translucent, which makes it a great choice for applications like greenhouse roofs or very large skylights.

Important Considerations Before Buying

- Purpose: Understand the specific requirements of your project. Consider factors like the local sun exposure and climate and appropriateness vis-à-vis expected structural loads and appearance.

- Service Life: Evaluate the desired lifespan and the potential need for and practicality of performing maintenance.

- Fire Resistance: Check your local code for fire safety standards. Ensure the fabric meets necessary requirements.

- Warranty and Support: Look for products with good warranties and high-level customer support from the manufacturer.

Importance of a Reputable Manufacturer

- Quality Assurance: The manufacture of tensile fabric is a highly technical process. Properly formulated materials, well-designed manufacturing techniques, and strict quality control are all vital to the production of acceptable tensile fabric products. Reputable manufacturers should be able to provide high-quality products that meet or exceed industry standards.

- Customization: An extremely high percentage of tensile fabric installations are custom jobs. You want a manufacturer who has an experienced design team who communicate well and are used to working with their customers.

- Qualified Contractors: Reputable fabric roofing manufacturers will typically only work with installers that they have trained or examined and should be able to provide you with a list of approved, certified contractors in your area.

- Technical Support: Reputable manufacturers will have a competent technical department that can provide necessary support during both the design and installation phases, as well as afterwards if any issues arise.

- Warranty: A reputable manufacturer will stand behind their product with comprehensive warranties and will be helpful when addressing any issues.

*****

If you are a reputable and qualified structural tensile fabric manufacturer and feel that we’ve overlooked your company, feel free to contact us to ask to be added to this list.