How to Use Roof Cement & Best Roof Cement Products (2024)

By Jack Gray, Roof Online Editor • Updated March 20, 2024

Table of Contents

Introduction

We’re professional roof consultants – professional roof experts, you might say. Our clients include homeowners associations, corporate real estate asset managers, property managers, and facility directors.

As a part of our job, we research and specify the materials for roof repairs, choosing the best roofing products to use on our clients’ roofs based on how the materials perform and how much they cost.

We’ve managed proactive maintenance programs and been responsible for millions of square feet worth of roofing. We’ve made thousands of repairs and gone through thousands of gallons of roof cement from various manufacturers.

Inspecting all of these roofs every year has allowed us to track the performance of roof patches as time goes by. This has given us a pretty good idea as to how the different brands perform.

We know roof cement pretty well, and we thought we would share some helpful information here on our website.

What is Roof Cement?

Roof cement is a black, sticky, highly viscous, asphalt-based material most often used to make roof repairs. It can be easily applied and worked with a trowel or putty knife. It can also be applied with a caulk gun when it comes in a tube.

Compatible roofing materials include asphalt shingles, concrete tile and other masonry, and metal, among others.

Roof cement is also known as roofing cement, flashing cement, plastic roof cement, roof mastic, pookie, and goop.

Roofing cement is a mixture of cutback asphalt (asphalt which has been thinned with a petroleum-based solvent) and mineral stabilizers, formulated to have a consistency that makes it easy to apply with a trowel or caulk gun. It may contain other additives that enhance its performance.

At its most basic, roofing cement in the container contains around 40% to 60% asphalt, 20% to 30% solvent, and 10% to 20% inert mineral fillers. Another 5% to 10% worth of cellulose or fiberglass fibers is almost always present as well.

Roof cement remains soft, plastic, and workable so long as it remains in its container with an airtight seal. Once it’s applied to the roof and exposed to the air, the solvent which keeps it soft begins to migrate out of the asphalt and evaporate into the air.

Once all the solvent is gone, the material becomes quite hard. This process is called “curing”.

How long it takes to cure depends on the product, the weather (humidity slows the process), and how thick the application is. In general, it will typically take about 6 to 12 hours to feel dry and start forming a hard skin, and up to 30 days to fully cure.

What is Roof Cement Used For?

Emergency Roof Leak Repairs

Roof cement is used to stop roof leaks. Emergency roof repairs are the immediate actions you take to stop a roof leak or potential roof leak with temporary measures until you have the time to make proper permanent repairs (or hire someone to make permanent repairs).

Roofing cement is the perfect material for a quick, temporary fix. You find the hole, fill the hole, and you’re done.

You can use many of these products to plug active leaks even when it’s raining. They will be identified as being “wet/dry” or “all weather” roofing cement.

Long-Term Roof Repairs

Using roof cement is usually not the best way to go about making permanent roof repairs. It has a much shorter useful life than the replacement roofing materials (new shingles or flashing material, for instance) that a professional roofer would use to repair a roof leak.

If applied properly, however, roof cement can be used to make long-lasting repairs on older roofs. These repairs can often last until the roof itself needs to be replaced.

Long-term roof repairs made with roofing cement should always be performed while the roof is completely dry, regardless of whether or not it’s called “wet/dry” or “all weather”.

Long-term roof repairs made with roof cement should be made using what is called a “3-course” or “5-course” application technique.

A 3-course roof patch has a base layer of roofing cement ⅛-inch to ¼-inch thick which extends at least 3 inches (preferably 6 inches) beyond the hole or crack in all directions.

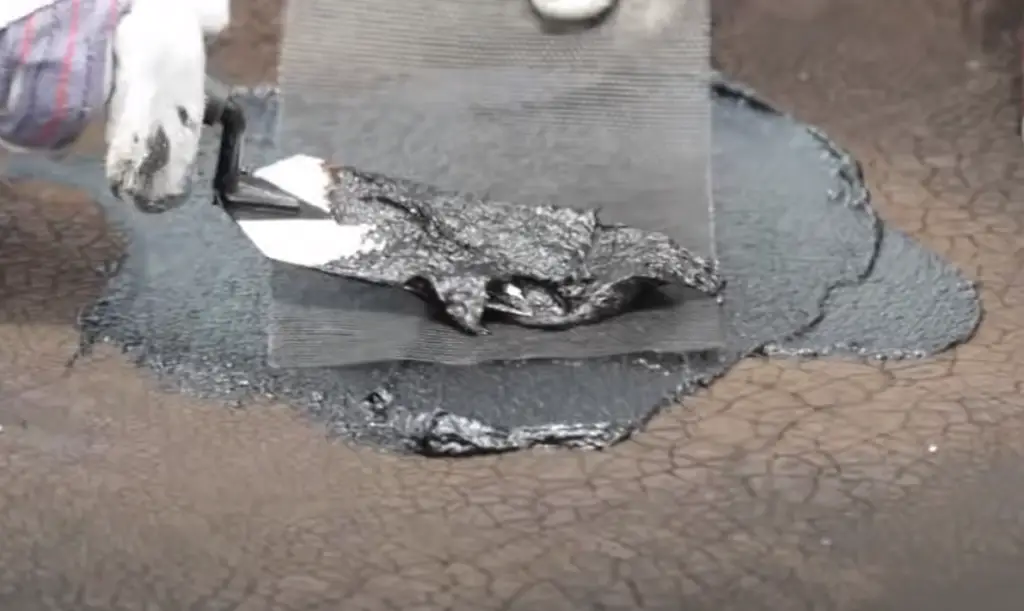

After the first layer of roof cement has been applied, a layer of mesh reinforcement fabric is set into the surface of the roofing cement. Larger patches may need several pieces of fabric mesh.

Once the reinforcement mesh is in place, another layer of roof cement is applied on top of it.

A 5-course roof patch is applied the same way, with an additional layer of fabric covered by an additional layer of roofing cement.

Remember that the UV rays of the sun are the biggest enemy of asphalt on a roof. That’s the main reason that all asphalt shingles have granules on them.

For long-term repairs, applying an asphalt-compatible protective roof coating over your patch (after it cures!) can as much as double its useful life.

This short video from Karnak shows you how to repair a roof using a 3-course fabric and mastic patch:

Adhering Loose Shingle Tabs

Hand sealing shingles is necessary if the factory-applied self-sealing strip on your shingles fails. Hand sealing is also a good practice in general for shingles on very steep slopes, in high wind areas, and when installing shingles in cold weather.

Loose shingle tabs can be a serious issue on asphalt shingle roofs. They can easily result in more serious damage to the shingles, as they make the shingles extremely susceptible to wind damage. When strong wind gets under the shingles and agitates them, the result is often torn, cracked, or completely missing shingles.

Even if the shingles aren’t actually damaged, loose shingles flapping in a rainstorm provide a pathway for wind-driven rain to get up under the shingles, where the water can find its way through the roof deck and into your house.

In order to prevent this from happening, you can use roof cement as an adhesive to secure the tabs. This is called “hand sealing” or “manual sealing”, and it’s the method recommended by roofing manufacturer technical departments and other roofing industry authorities.

To manually seal loose shingle tabs, apply one spot of roofing cement under the center of each tab of a 3-tab shingle. For laminated shingles without individual tabs, space the three spots equally along the shingle length.

Two additional spots, one at each outside corner of the entire shingle, should be applied in high-wind regions.

The spots should be about 1” (25 mm) in diameter. All spot applications should be applied so that the edge of the spot is back about one inch from the edges of the shingle, so that the material doesn’t ooze out and become visible when you press the shingle down.

Once the roof cement has been applied, lower the loose shingle back down onto the shingle beneath it and firmly press the shingle tabs down to form a good bond.

When adhering loose shingles, you should use material that comes in a tube and apply it using a caulk gun rather than a trowel. This method is far, far easier and faster than trying to hand seal shingles with a trowel.

Other Uses for Flashing Cement

Plastic roof cement also has various applications during the installation of a roof, primarily related to the installation of flanged metal roof components such as edge metal, vent pipe flashings, the metal flange or stripping around many roof drains, and flanged metal pitch pans.

In these cases, the product specifications will often call for the flanges to be set into a bed of roofing cement. When used this way, it serves both as an adhesive to hold the metal flanges in place, as well as a secondary water barrier to prevent leaks at these locations.

Flashing cement will also be used during standard roof maintenance activity, particularly as a material for topping off pitch pans or filling partially opened laps in modified bitumen base flashings.

What Materials Are Compatible with Roof Cement?

When it comes to compatibility, the important thing to remember is that when roofing cement comes out of the can, it contains quite a bit of solvent. Although some materials, like flexible PVC, are simply incompatible with asphalt, roof cement is 10% to 30% solvent by weight, and it’s the solvent that causes many of the compatibility issues.

For plastics, vinyl, synthetic underlayments, roof coatings, and factory-coated or painted materials, it’s best to double-check with the manufacturer’s technical department before applying roofing cement.

Materials that Are Compatible with Roof Cement

- Asphalt Built-up Roofing

- Asphalt Shingles

- Asphaltic Roofing Felt (“Tar Paper”)

- Brick

- Clay or Concrete Tile

- Concrete Masonry

- Metal – All Uncoated Metal

- Metal – Most Coated Metals

- Modified Bitumen (SBS)

- Roll Roofing

- Slate Roofing

- Stone Masonry

- Terra-Cotta

Materials that Are Not Compatible with Roof Cement

You should be aware that using an incompatible material to repair, alter, or modify a roof may void your roof warranty. If your roof is under warranty, you should read the warranty or call the technical department of the roofing manufacturer to make sure that it’s ok to use roofing cement.

APP Modified Bitumen – Most flashing cements are compatible with APP-modified bitumen, but some do contain additives which can be detrimental to the long-term performance of APP-modified bitumen. Check with the manufacturer’s technical department to find out which roof cement products are compatible with their mod bit products.

Coal Tar Pitch Roofing – Asphalt-based roof cement is not recommended for long-term applications, but may be used for emergency leak repairs.

It takes a while for asphalt to damage coal tar pitch, so you should have time to make permanent repairs (and remove all of the asphalt and affected roofing) before the damage starts to get serious. Compatible roof mastic made from coal tar pitch is still being manufactured.

EPDM Roofing – Roofing cement is completely incompatible with EPDM roofing. The solvent in the roofing cement attacks and disintegrates EPDM. Do not use roof cement on an EPDM roof!

PVC Roofing – Roof cement is completely incompatible with flexible PVC (PVC roof membranes) due to the plasticizers used in the PVC. Roofing cement should not be an issue for rigid or hard PVC like PVC house trim, PVC pipe, or PVC gutters.

Silicone Coatings or Sealants – As a very general rule, you should treat silicone roof coatings as if they were incompatible with anything else, unless the product data sheet says otherwise.

Synthetic Shingles – Synthetic composite shingles are made with a variety of polymer formulations. There’s a high risk that roof cement will cause damage or fail to form a long-lasting bond with some synthetic shingles.

Check with the manufacturer’s technical department before using roofing cement on synthetic shingles.

TPO Roofing – Roof cement is not recommended for long-term applications, but may be used for emergency leak repairs if you’re planning on having proper repairs done eventually by a professional roofer.

Roofing cement does not cause rapid severe damage to TPO roof membranes like it does with PVC or EPDM.

However, you should note that roofing manufacturers do specifically warn against using roofing cement with TPO. Firestone says “do not use oil-base or bituminous-base roof cement with any Firestone TPO products”. Asphalt is “bituminous”.

What the Best Roof Cements Have in Common

The Best Roof Cements Are “Fibered”

The best roof cement is fibrated, which means that it contains short cellulose or fiberglass fibers. The fibers are typically between ¼ inch and 1 inch long. These fibers stabilize the cement.

The fibers increase the roofing cement’s resistance to flow while it’s being applied and while it’s curing. This improves its performance on steeper roofs, and it means you don’t have to worry about the material sliding out of place and down the roof before it has a chance to harden.

All of the best roof cements will be fibered.

The Best Roof Cements Are “Rubberized”

Roofing cement can be rubberized, and the best of them are. Much the same way that the best roof shingles are made with polymer-modified asphalt, the best roof cement will contain roughly 3% to 10% synthetic rubber.

The rubber will often be SBS (styrene-butadiene-styrene), which is the same material used in impact-resistant shingles and one type of the modified bitumen material used on flat roofs.

Rubberized roofing cement is particularly good for permanent or long-term repairs. A common problem with basic, non-rubberized roof cement is that it shrinks and hardens, losing strength and flexibility over time.

This can cause patches made with basic roofing cement to crack and split after about six months to a year, especially if the patch is applied without using reinforcement fabric.

The rubber in the roof cement helps it resist shrinking and cracking. It also performs better in cold weather and can be applied during much colder temperatures than regular roofing cement. Rubberized roof cement is also impact-resistant, which helps it survive hail storms.

Rubberized roofing cement can be much more expensive than the regular stuff. But if you’re using it for anything other than emergency or temporary repairs that you’ll be replacing soon, you’ll want to use the best roof cement you can.

You’ll be better off in the long run if you spend the extra money.

The Best Roof Cements Have High Production Quality

The best roof cement products are manufactured to high standards, using industry best practices, with a final product that is consistently satisfactory.

Of course, you won’t be able to observe it being made or see the actual quality standards being enforced in the factory, so you’ll just have to take the manufacturer’s word for it. Which brings us to manufacturer reputation.

The Best Roof Cements Are Made by a Trusted Manufacturer

The best roofing materials are made by manufacturers with a great reputation. A great reputation is the result of years of producing quality products, treating their customers well, honoring their warranties, and being honest about what their products can and cannot do.

If a manufacturer has a good reputation, that’s a good indication that you will get what you think you’re paying for when you buy something from them.

All of the products we list below are made by companies that have a good reputation within the roofing industry.

How Much Roof Cement Do You Need?

A proper 3-course or 5-course roof patch made with roofing cement and fabric is going to be ½-inch to ¾-inch thick. A proper patch is also going to extend six inches beyond the damaged area in all directions. Even a small hole will require at least a one square foot patch.

A 5-course roofing cement patch that covers one square foot and is ¾-inch thick will require one half gallon of roof cement.

Larger patches will need quite a bit more. If you’re patching the flashing all the way around a chimney, for instance, you’ll need about 4 gallons. If you’re patching an entire roof-to-wall joint, you’ll need half a gallon per foot to do it right. 10 or even 20 gallons of roofing cement may be necessary.

For hand-tabbing shingles, you can figure on getting around 30 spot applications of roof cement out of a 10-ounce tube, which should be enough for 5 – 10 shingles, depending on how thorough you need to be.

Try not to buy quart cans of roof cement if you can help it. The price per ounce is far higher than it is for a larger container. And you can’t really do anything with a quart of roofing cement except make one or two very small emergency leak repairs. Better to keep at least a gallon around for when you need it.

List of the Best Roof Cement Products

Please Note: Make sure you pay attention to the quantity when you order one of these products through the links we provide. These links might take you to a 5-gallon, 3-gallon, 1-gallon, or caulk tube product page. You should be able to find the size you’re looking for once you’re there, though.

Karnak 19 Ultra Rubberized Flashing Roof Cement

Why it’s one of the best roof cements:

We like this stuff a lot. When we have to make roof repairs or roof alterations, or use roof cement as part of some other type of roofing project, this is what we generally use. We know it’s a high-quality product from a good company.

We do sometimes use other products, but after years of experience, this is our favorite. With this stuff, we don’t have to worry about performance issues, application difficulties, or premature failure.

It may not be be that much better than some of the other products on this list, but we’ve found it to be good and reliable, and we’re sticking with it, and a lot of contractors we know feel the same way.

Website:

Where to buy:

See Karnak 19 Ultra at Home Depot

Black Jack Premium Roof Cement

Why it’s one of the best roof cements:

Black Jack is a very old name in roofing cements. Black Jack has been around for over a century, and in that time it has developed an excellent reputation in the residential roofing industry.

Many, many roofers consider Black Jack to be the best roof cement without question. It’s their reliable go-to, and always will be. They always make sure to have some around. Some roofers simply say “Black Jack” when they mean “roof cement”.

This is a basic, non-rubberized roofing cement, and it’s the best you can get for emergency leak repairs or other applications where rubberized roofing cement isn’t called for.

Website:

Where to buy:

See Black Jack Premium Roof Cement on Amazon

Henry 208 Wet Patch Roof Leak Repair

Why it’s one of the best roof cements:

Henry roofing cement is kind of the standard. When a lot of people imagine a can of roof cement, a can of Henry is probably what they’re thinking of.

The general feeling in the roofing community is that Henry roofing cement doesn’t have quite as high a reputation as Black Jack, but it almost does. It may not be the absolute best roof cement, but then again, the product isn’t quite as expensive as Black Jack, either.

This roofing cement is basic, it’s not rubberized, so it’s fairly inexpensive.

Henry has the best-selling roof cement in America for a couple of reasons: high quality and reasonable price.

Website:

Where to buy:

See Henry 208 Wet Patch Roof Leak Repair on Amazon

See Henry 208 Wet Patch Roof Leak Repair at the Home Depot

Henry 208R SBS Rubber Modified Wet Patch Roof Cement

Why it’s one of the best roof cements:

Henry has an excellent reputation, and they have consistently high standards for all their roofing cement products. If you’re planning on making long-term roof repairs, you’re going to want a high-quality rubberized roofing cement.

If you’re hoping that your repairs will last until the roof has to be replaced, you don’t want to try and save a few dollars by using an inferior product.

Henry 208R SBS Rubber Modified Wet Patch can be reliably used for both temporary repairs and long-term repairs.

Website:

Where to buy:

See Henry 208R SBS Rubber Modified Wet Patch Roof Cement at the Home Depot

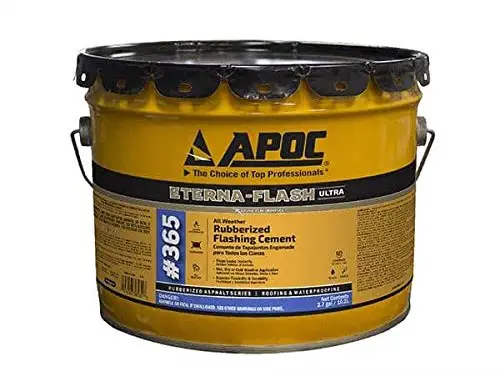

APOC 365 Eterna-Flash All Weather SBS Flashing Cement

Why it’s one of the best roof cements:

APOC is another company that’s been making roofing products in the USA for over a century, so they’re clearly doing something right.

If you want an excellent rubberized roofing cement, this should do the trick.

APOC 365 Eterna-Flash is a high-quality product that gets great reviews from roofers and homeowners alike. If you’re looking to make long-lasting repairs on your roof, this is some of the best roof cement you can use.

Website:

Where to buy:

See APOC 365 Eterna-Flash All Weather SBS Flashing Cement on Amazon

Gardner Wet-R-Dri All Season Roof Patch

Why it’s one of the best roof cements:

It’s always a good idea to keep a can of roofing cement around in case of emergencies. This might not technically be one of the best, but it’s a good product to just keep in the garage in case you ever need it.

This product is a lot cheaper than the others on this list. If you just want to have something around in case you need to repair a sudden unexpected roof leak, this will do the job just fine.

Remember that even the best roof cement has a shelf life of around 12 to 24 months. If there’s a good chance that you might not even use most of the material before it goes bad, why spend the extra money? If you need to, you can get the really good stuff to make more permanent repairs later.

Website:

Where to buy:

See Gardner Wet-R-Dri All Season Roof Patch on Amazon

What Else You Need to Apply Roof Cement

Trowel (See on Amazon)

Use a trowel to make your roof repairs unless you are applying adhesive spot applications under roof shingles. You cannot spread the roof cement properly without a trowel (unless you use your hands, see rubber gloves below).

High-Thrust Caulk Gun (See on Amazon)

If you are using the roofing cement to adhere loose shingles, buy it in a tube and apply it with a caulk gun. You will not be able to apply it with enough precision otherwise. You’ll make a serious mess with a trowel.

Reinforcement Fabric (See on Amazon)

All proper roof repairs made with roof cement will consist of at least two layers of roof cement with a mesh reinforcement fabric in the middle. Patches that are not reinforced this way will crack, split, and fail far sooner than a fabric-reinforced patch.

Disposable Rubber Gloves (See on Amazon)

Wearing protective, disposable gloves when you work with roof cement is a good idea because they’ll keep your hands clean and if you get this stuff on your nice work gloves, you aren’t going to get it off.

Another thing to think about – a lot of roofers, if they have a large area to patch, will put on disposable gloves and spread the roof cement with their hands instead of using a trowel.

They scoop it out of the can with their hands, and work it into position with their hands. This makes the work go a LOT faster.

If you decide to try this method, you should cut your reinforcement fabric to size before you start to apply the material so you don’t have to take your gloves off to use the scissors in the middle of the operation.

Protective Roof Coating (See on Amazon)

When UV rays hit asphalt, they break the long-chain asphalt molecules into smaller and smaller fragments over time. This weakens the asphalt and makes it more and more fragile. The more fragile the asphalt is, the easier it cracks, splits, and generally falls apart.

If you want your repairs to last, you need to protect them from the sun. An asphalt compatible roof coating can greatly extend the life and improve the performance of your repair patch.

Coatings should be applied after the patch has had time to fully cure.

About the Author

Jack Gray is a principal roof consultant and vice president at the Moriarty Corporation, an award-winning building enclosure consultant firm founded in 1967. He is also the editor of the Roof Online website.

Mr. Gray has worked in the roofing industry for over 25 years, with training and practical experience in roof installation, roof inspection, roof safety, roof condition assessment, construction estimating, roof design & specification, quality assurance, roof maintenance & repair, and roof asset management.

He was awarded the Registered Roof Observer (RRO) professional credential in 2009.

He also served as an infantry paratrooper in the 82nd Airborne Division and has a B.A. from Cornell University. Read full bio.

Related Articles

Asphalt Shingle Roofing: Useful Information Guide

Best Roof Repair Tape • Top 5 Roof Sealant Tapes

Best Roof Shingles • Top 7 Shingle Brands

How Long Does a Roof Last? • Roof Lifespan for 49 Roof Types

How Much Does an Asphalt Shingle Roof Cost?

How to Replace a Missing Asphalt Shingle

Modified Bitumen 101 • Important Facts and Guidelines

Roof Nail Pops 101 • Roof Nail Pop Repair Guide

ASTM Standards

Asphalt roof cement is categorized by ASTM standard D 2822-91 (1997) or for non-asbestos, ASTM standard D 4586-93.

- Flashing Cement can be used on vertical surfaces and has a high softening point, low ductility and conforms to the requirement of ASTM Specification D 312, Types II or III; or Specification D 449, Type III.

- Plastic Cement is for use on low-slope surfaces, conforms to ASTM Specification D 312, Type I; Specification D 449, Types I or II; or Specification D 946. Plastic Cement is self-sealing, adhesive and ductile and is classified by ASTM Standard D 2822-91 Asphalt Roof Cement, and D 4586-92 Asphalt Roof Cement, Asbestos-Free, Types I and II.